How Proper Tyre Pressure Saves Your Fleet Money

Tyre Pressure and Fuel Consumption: The Hidden Cost You Can’t Ignore

Fuel is the largest ongoing expense for long-distance trucks. Even a small increase in fuel usage can add up to thousands of rand over the year. Incorrect tyre pressure is one of the leading causes of unnecessary fuel consumption.

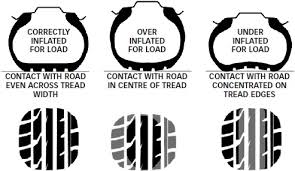

Underinflated Tyres Increase Rolling Resistance

When tyres are underinflated, more of the rubber surface touches the road. This increases rolling resistance, which forces the engine to work harder to move the vehicle. As a result:

- Fuel consumption increases

- The truck loses power and efficiency

- The engine experiences unnecessary strain

Studies show that underinflation can increase fuel usage by up to 10%, which is a massive cost for trucks travelling thousands of kilometres each month.

Overinflation Is Also a Problem

Overinflated tyres may slightly lower rolling resistance, but they cause:

- Reduced traction

- Uneven wear

- A harsher ride

- Higher risk of blowouts

In the long run, overinflation costs more than it saves.

The Impact of Tyre Pressure on Tyre Lifespan

Tyres are a major investment for any fleet. Proper pressure significantly extends their lifespan by ensuring that the tread wears evenly across the tyre.

Underinflation Causes:

- Excess heat

- Faster shoulder wear

- Sidewall damage

- Increased chance of punctures

Overinflation Causes:

- Fast centre tread wear

- Reduced ability to absorb road impacts

- Premature casing damage

- Higher blowout risk

Maintaining correct pressure can extend tyre life by 20–30%, reducing the number of replacements needed each year.

Safety Benefits That Save Money and Prevent Breakdowns

Safety is directly connected to tyre pressure. Incorrect pressure makes the truck harder to control and increases the risk of roadside emergencies — which are expensive and dangerous.

Proper pressure improves:

- Braking performance

- Cornering stability

- Trailer control

- Steering response

- Load-bearing strength

A tyre blowout at high speed can cause serious accidents, delays, damaged cargo and costly recovery services. Maintaining optimal pressure is one of the easiest ways to prevent this.

Pressure Monitoring: A Smart Investment for Every Fleet

Traditional manual checks are important, but many fleets now use digital systems to increase accuracy.

Digital Tyre Gauges

These offer quicker, more precise readings and help eliminate human error.

Tyre Pressure Monitoring Systems (TPMS)

TPMS devices constantly monitor tyre pressure and temperature. They alert drivers or fleet managers immediately when a tyre drops below the safe pressure range.

This prevents:

- Unexpected breakdowns

- Costly roadside repairs

- Excess tyre wear

In the long term, the savings from TPMS far outweigh the initial cost.

Recommended Pressure Checks for Maximum Savings

To keep tyres in perfect condition:

- Check pressure weekly

- Check before every long-distance trip

- Check when temperatures change

- Check after loading heavy cargo

Even a small pressure drop of 10–15% can dramatically affect performance and costs.

Conclusion

Proper tyre pressure is one of the most powerful money-saving tools in the trucking industry. It reduces fuel consumption, extends tyre life, enhances safety and improves overall vehicle performance. By making tyre pressure a regular part of your maintenance routine, you can significantly cut operating costs and keep your fleet performing at its best — mile after mile.